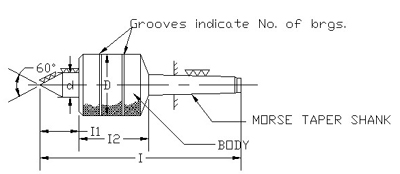

Nomenclature

Revolving CentresLive Centres

Ball bearing Centres

Description & Features

The Our Rotating Centres are made to IS Specifications. The Rotating Centres are capable of withstanding axial loads, thrust and radial loads.The housings (or body) of the Rotating Centres are made of low carbon alloy steel, hardened to 30-40 HRC. The spindles are made of ball-bearing alloy steel, and hardened to 60-62 HRC.

The spindles are mounted with bearings to ensure smooth running. The housings are provided with oil nipples for frequent lubrication, to maximize life of bearings.

The alignment between the shank and front spindle is kept within 0.015mm. and the cone runout ( W.r.t. cone and taper angle) is kept within 0.005mm.

| Tapper | d Min | D Max | I #1 | I2 Max | I Apprpx |

| Morse 1 Morse 2 Morse 3 Morse 4 Morse 5 Morse 6 |

12 18 24 28 36 56 | 35 45 60 70 75 100 |

20 24 28 36 40 56 |

42 45 56 75 80 90 |

120 140 170 220 255 355 |

Care in use

Due to axial and thrust loads, the bearings may get heated up and damage the spindle. This happens when higher loads and speed (rpm) are used than what is specified. It is therefore, very necessary to select the correct Rotating Centre.Frequent cleaning and lubrication are necessary to maximize the life of Rotating Centres.

Rotating Centres must be protected from metal particles and dust entering the bearing hosing.

When not in use, protect the shanks of Rotating Centres by applying rust preventives.