Description & Features

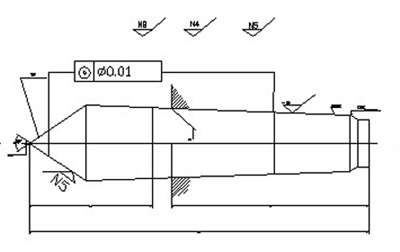

The Our Plain Centers are made from carbon-chromium alloy steel hardened to 62 HRC to withstand wear. The Plain centres have a high surface finish to allow maximum bearing on master gauges. The runout with respect to cone and taper angle is kept within 0.005mm.

| Designation of Taper Type Metric 5 Percent Morse | No | Taper On Dia | d1 | d2 h9 | d3 | I 1 Max | I 2 Max | I4 Max |

| 4 6 0 1 2 3 4 5 6 |

0.05 0.05 0.05205 0.04988 0.04995 0.05020 0.05194 0.05263 0.05214 |

4.000 6.000 9.045 12.065 17.780 23.825 31.267 44.399 63.348 |

4.1 6.2 9.2 12.2 18.0 24.1 31.6 44.7 63.8 |

0.3 0.3 0.5 0.5 0.8 0.8 1.0 1.6 2.0 |

23.0 32.0 50.0 53.5 64.0 81.0 102.5 129.5 182.0 |

33 47 70 80 100 125 160 200 270 |

8 12 17 23 31 39 51 64 80 |

Care in use

Thoroughly clean the machine spindle nose before mounting precision grinded Plain Centres, to avoid damage.Take utmost care to protect the taper portion from denting or bending to avoid damage to the machine spindle

Take care to mount the Plain Centres perfectly. This will minimise runouts.