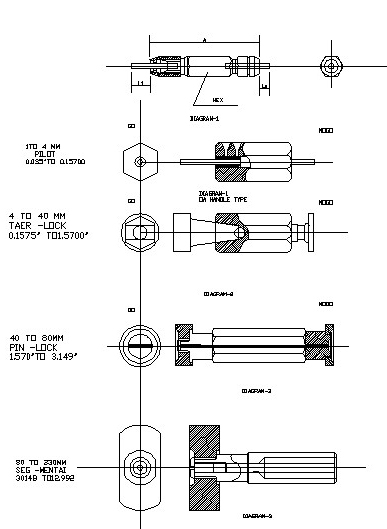

“Go and No – Go” Gauge ( for checking bores)

Double – ended Plug Gauge

Description & Features:

The Our Plug Gauges are made of superior quality high carbon chrome alloy steel, hardened to 58-60 HRC, to provide a high degree of wear resistance.The Plug Gauges are manufactured to close tolerances, and properly stabilized to prevent dimensional distortions and ensure stability throughout their use .

|

HANDLE NO. |

SIZE RANGE NOMINAL |

A |

HEX

A/F |

L GO |

L NOGO |

|

Above |

To and INCL |

|||||

1W |

1 |

2 |

50 |

7 |

8 |

5 |

2W |

2 |

4.5 |

77 |

10 |

15 |

12 |

3W |

4.5 |

7 |

85 |

16 |

18 |

15 |

4W |

7 |

10 |

90 |

19 |

20 |

15 |

5W |

10 |

13 |

110 |

22 |

22 |

17 |

6W |

13 |

16 |

115 |

25 |

22 |

17 |

7W |

20 |

20 |

120 |

27 |

22 |

17 |

Specify the diameters of the bores to be measured and their manufacturing tolerances. One the tolerances are specified the Plug Gauge designs are automatically selected as per IS, BS, DIN standards.

Specify if the Gauges are to be used to measure ‘blind’ holes, so that necessary air vents can be provided to prevent air locks.

Note: Normally up to 10% of the manufacturing tolerance (of the bore) is required to make Gauges.