Nomenclature:

a) Electro – magnetic Table

b) Electro – magnetic Plate

c) Electro-magnetic Bed

Description & Features:

The Our rectangular Electro-magnetic Chucks (EM Chucks) are designed to achieve maximum pole saturation. And hold jobs, in the case of power failure, with the help of residual magnetism in the top plate.The top plate of EM Chucks can be provided with oscillating type poles, or lateral poles, if required.Scope of Supply:

Since EM Chucks operare on DC,along with an EM Chuck a Rectifier Unit is supplied if DC power is not available at the machine. Also, a program Controlled, On/Off and Demagnetisation Switch is provided, whenever such switch is not available on the machine. The EM Chucks are supplied usually with a 1 metre cable.Common uses

The Our EM Chucks are mostly used on surface grinding machines for holding jobs.The EM Chucks can also be used for milling and drilling operations.’

The EM Chucks are ideal for use with top plate/table size larger than 600 mm (24) as these are comparably more compact and lighter to operate than permanent magnetic chucks, and at the same time provide more gripping power.

Selection of EM Chucks

The selection of Our EM Chucks dependent on the 'table' capacity of the grinding machine (or milling/drilling machine). Close pole chucks are suitable for small and slim jobs. For heavy jobs, to get a powerful grip, normal pole chucks should be used, with the job covering at least two sets of N-S poles.If EM Chucks with the power sources other than 110V DC are required. e.g., 24 V DC or 220 V DC, the requirement should be clearly specified. Also, if cable length more than 1 metre is required, please specify the length needed.

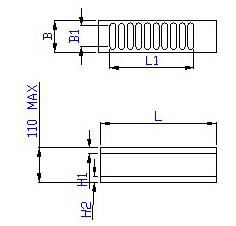

HYDROLIC ROTATING CYLINDER-DIMENSIONAL DATA

Nominal

Size B x L |

B1 Min |

L1 Min |

H1 Min |

H2 Approx |

125 x 250 150 x 300 150 x 450 200 x 600 250 x 1000 250 x 1500 300 x 1000 300 x 1500 |

100 120 120 160 210 210 250 250 |

180 220 360 520 900 1400 900 1400 |

16 16 18 18 20 20 20 20 |

16 16 16 16 20 20 20 20 |

Care in use

All electrical connections should be properly secured. Ensure coolants, lubricants, etc., do not fall on the Rectifier & On – Off Switch units.