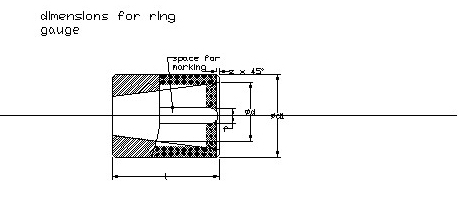

Self – release 7/24 Taper Gauges

Description & Features:

The Our ISO Taper Gauges, both plug and ring types, are made of superior quality high carbon chrome alloy steel, hardened to 58-60 HRC, to provide a high degree of wear resistance.The Taper Gauges are fine lapped to get maximum seating and surface finish. The Taper Gauges are rough ground and kept for a long period of time before finishing is given; this is done to prevent any distortions and ensure stability through their use.

7/24 Tapper Number |

D |

L |

D |

F |

F |

30 |

31.75 |

49.2 |

60 |

10 |

1.6 |

40 |

44.45 |

65.6 |

70 |

12 |

1.6 |

45 |

57.15 |

84.8 |

85 |

12 |

1.6 |

50 |

69.85 |

103.7 |

100 |

12 |

2.0 |

55 |

88.90 |

132.0 |

120 |

15 |

2.0 |

60 |

107.95 |

163.7 |

144 |

20 |

3.0 |

65 |

133.35 |

200.1 |

170 |

20 |

4.0 |

70 |

165.10 |

250.6 |

200 |

22 |

4.0 |

75 |

203.20 |

350.8 |

245 |

25 |

5.0 |

80 |

254.00 |

390.8 |

300 |

30 |

6.0 |

Care in Use

All Taper Gauges must be stored carefully in a dust free environment, and protected with periodic application of rust preventives.Before and after use, the Gauges must be cleaned with a smooth cloth or chamois leather. After use, the Gauges are best protected by applying a coat of rust preventive and kept wrapped in oil paper.