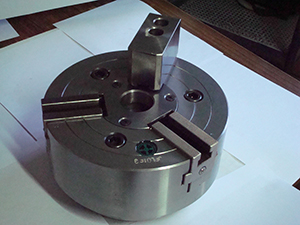

Description & Features

The Sonalkar Power Chucks are designed and constructed to hold heavy loads during long operation time, The Chucks effectively convert axially transmitted forces on a job into radial forces at the jaws, through the wedges. This conversion of forces, both low and high chuking forces. Also, the chucks have an internal locking system to ensure jobs do not fly-off. The chuck body in made of forged steel with the guideways specilly hardend and then ground to a smooth finish. The wedge slide is made of nickel chromium steel and case hardened, and all working surfaces are well ground. The base jaws with serrations on top face are also made of nickel chromium steel and case hardened.The jaws are grounded to perfectly match both the wedge and guide-ways. The base jaws are guided by deep and wide hardened slots in the chuck body, to ensure ample load bearing area to withstand resultant clamping forces. For periodic mannual lubrication of the sliding surfaces grease nipples have been provided. The reversible hard jaws have serration at the bottom to match the base jaws. Hard jaws of various radii are available to hold a wide range of jobs.

Scope of Supply

The sonalkar Power Chucks are supplied with a set of soft jaws and mounting bolts. The Power Chucks are also supplied with pneumatic, hydraulic or electrical power system including essential accessories -power chuck body, chuck flange, cylinder flange, drawbar, hoses and direction control valves. With pneumatic, lubro control unit, non-return valves are provided.

Sl. No |

1 |

2 |

3 |

4 |

Chuck Size |

160 x 3 |

200 x 3 |

250 x 3 |

315 x 3 |

| A |

160 |

200 |

250 |

315 |

B |

81 |

93 |

93 |

98 |

C |

6 |

6 |

6 |

6 |

| D |

150 |

185 |

185 |

300 |

F PCD |

125 |

160 |

140 |

250 |

| G |

M 12 |

M 12 |

M 16 |

M 20 |

| H |

M 27 x 2 |

M 42 x 1.5 |

M 56 x 2 |

M 64 x 2 |

| I |

17.0 |

37.0 |

48.0 |

60 |

J |

M 10 |

M 12 |

M 14 |

M 16 |

K |

M 16 |

M 20 |

M 20 |

M 20 |

L |

40 |

40 |

50 |

60 |

M |

31.5 |

35 |

35 |

35 |

N |

38 |

38 |

45 |

45 |

O |

12 |

14 |

17 |

21 |

P |

25 |

30 |

35 |

40 |

R |

70 |

70 |

80 |

100 |

Max. Speed in R.P.M. |

2000 |

1800 |

1600 |

1200 |

Draw bar Pull at 7Kg/Cm2 |

1280 |

2130 |

3680 |

5380 |

Jaw Movement |

4 |

5 |

6 |

7 |

Weight in Kgs App. |

11 |

19 |

31 |

60 |