Nomenclature

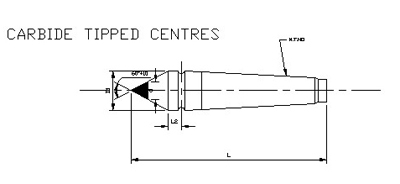

Carbide Tipped Dead centresCarbide tipped Plain Centres

Centres for Grinding Machines

Description & Features

The Our carbide Tipped Centres (CT) are made of alloy steel shank fitted with tungsten – carbide tips by brazing. The shanks are made of low carbon steel hardened to 40 HRC. The cones where the carbide tips are mounted are given a fine surface finish.Common Uses

The Our CT Cetres are mainly used on grinding machines. On high rpm lathes use of these CT Centres are recommended.Selection of CT centres

The selection depends on the spindle nose of a machine and carbide tip bearing area required area required for a job.

| M.T. Capacity | D | DI | D | L | L1 | L2 |

| 1 | 12.056 | 12.2 | 7 | 80 | 53.5 | 2 |

| 2 | 17.780 | 18 | 7 | 100 | 64 | 7 |

| 3 | 23.825 | 24.1 | 11 | 125 | 81 | 7 |

| 4 | 31.267 | 31.6 | 14 | 160 | 102.5 | 9.2 |

| 5 | 44.369 | 44.7 | 18 | 200 | 129.5 | 15 |

| 6 | 63.348 | 63.8 | 18 | 270 | 182 | 3 |

Care in use

Thoroughly clean the machine spindle nose before mounting the precision grinded CT grinded CT centres, to avoid damage.Take utmost care to protect the taper portion from denting or bending, to avoid damage to the machine spindle.

Take care to mount the CT Centres perfectly. This will minimise runouts.