Nomenclature

The Morse Taper (MT) Gauges are also known as Self-holding Tapers.

The Morse Taper (MT) Gauges are also known as Self-holding Tapers.

Description & Features:

The Our Morse Taper Gauges ( MT Gauges ) are made of superior quality high chrome alloy steel hardened to 58-60 HRC, to provide a high degree of wear resistance. The MT Gauges are fine lapped to get maximum seating and surface finish. The MT Gauges are rough ground and kept for a long period of time before finishing is given; this is done to prevent any distortions and ensure stability throughout their use.

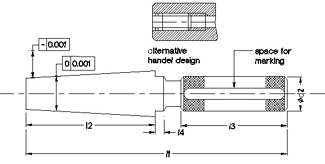

TABLE 1 DIMENSION OF TAPER PLUG GAUGES, PLAIN

Designation of Taper |

d js5 |

d2 |

1 |

I Js8 |

I3 |

I4 |

Z #0.05 |

∝/2 |

AT µm |

MT 0 |

9.045 |

9 |

116 |

50 |

53 |

3 |

1.0 |

1’ 29’27 |

+4.0 |

MT 1 |

12.065 |

11 |

128 |

53.5 |

63 |

3.5 |

1.0 |

1’ 25’43 |

+4.3 |

MT 2 |

17.750 |

13.5 |

148 |

64 |

70 |

5 |

1.0 |

1’ 25’50 |

+4.0 |

MT 3 |

23.825 |

17.5 |

176 |

81 |

80 |

5 |

1.0 |

1’ 26’16 |

+5.1 |

MT 4 |

31.267 |

25 |

210 |

102.5 |

90 |

6.5 |

1.5 |

1’ 29’15 |

+5.1 |

MT 5 |

44.399 |

34 |

250 |

129.5 |

100 |

6.5 |

1.5 |

1’ 30’26 |

+6.5 |

MT 6 |

63.348 |

34 |

316 |

182 |

110 |

8 |

2.0 |

1’ 29’36 |

+7.3 |

ME 4 |

4 |

7 |

80 |

23 |

48 |

2 |

0.5 |

1’ 25’56 |

+2.9 |

ME 6 |

6 |

7 |

90 |

32 |

48 |

3 |

0.5 |

1’ 25’56 |

+3.2 |

ME 80 |

80 |

34 |

330 |

196 |

110 |

8 |

2.0 |

1’ 25’56 |

+7.8 |

ME 100 |

100 |

34 |

370 |

232 |

110 |

10 |

2.0 |

1’ 25’56 |

+9.3 |

ME 120 |

120 |

40 |

410 |

268 |

110 |

12 |

2.0 |

1’ 25’56 |

+8.4 |

ME 160 |

160 |

40 |

560 |

340 |

110 |

16 |

3.0 |

1’ 25’56 |

+10.9 |

ME 200 |

200 |

40 |

630 |

412 |

110 |

20 |

3.0 |

1’ 25’56 |

+10.3 |

I2 as per IS : 7615- 1975 ‘System of cone tolerance”.

TABLE 2 DIMENSION OF TAPER PLUG GAUGES, TANGED

Designation of Taper |

d js5 |

d h 11 |

d2 |

1 |

I Js8 |

I3 |

I4 |

Z>#0.05 |

a/2 |

AT>µm |

MT 0 |

9.045 |

6 |

9 |

116 |

50 |

53 |

3 |

1.0 |

1’ 29’27 |

+4.0 |

MT 1 |

12.065 |

8.7 |

11 |

128 |

53.5 |

63 |

3.5 |

1.0 |

1’ 25’43 |

+4.3 |

MT 2 |

17.750 |

13.5 |

13.5 |

148 |

64 |

70 |

5 |

1.0 |

1’ 25’50 |

+4.0 |

MT 3 |

23.825 |

18.5 |

17.5 |

176 |

81 |

80 |

5 |

1.0 |

1’ 26’16 |

+5.1 |

MT 4 |

31.267 |

24.5 |

25 |

210 |

102.5 |

90 |

6.5 |

1.5 |

1’ 29’15 |

+5.1 |

MT 5 |

44.399 |

36 |

34 |

250 |

129.5 |

100 |

6.5 |

1.5 |

1’ 30’26 |

+6.5 |

MT 6 |

63.348 |

51 |

34 |

316 |

182 |

110 |

8 |

2.0 |

1’ 29’36 |

+7.3 |

ME 80 |

80 |

67 |

34 |

330 |

196 |

110 |

8 |

2.0 |

1’ 25’56 |

+7.8 |

ME 100 |

100 |

85 |

34 |

370 |

232 |

110 |

10 |

2.0 |

1’ 25’56 |

+9.3 |

ME 120 |

120 |

102 |

40 |

410 |

268 |

110 |

12 |

2.0 |

1’ 25’56 |

+8.4 |

ME 160 |

160 |

138 |

40 |

560 |

340 |

110 |

16 |

3.0 |

1’ 25’56 |

+10.9 |

ME 200 |

200 |

174 |

40 |

630 |

412 |

110 |

20 |

3.0 |

1’ 25’56 |

+10.3 |

TABLE 1 DIMENSION OF TAPER PLUG GAUGES, PLAIN

Designation of Taper |

d js5 |

d2 |

d3 |

I k8 |

2 |

c |

a/2 |

AT µm |

MT 0 |

9.045 |

20 |

50 |

2 |

1’ 29’27 |

+4.0 |

||

MT 1 |

12.065 |

28 |

53.5 |

2 |

1’ 25’43 |

+4.3 |

||

MT 2 |

17.750 |

38 |

64 |

2.5 |

1’ 25’50 |

+4.0 |

||

MT 3 |

23.825 |

46 |

81 |

2.5 |

1’ 26’16 |

+5.1 |

||

MT 4 |

31.267 |

55 |

102.5 |

2.5 |

1’ 29’15 |

+5.1 |

||

MT 5 |

44.399 |

72 |

129.5 |

2.5 |

1’ 30’26 |

+6.5 |

||

MT 6 |

63.348 |

95 |

182 |

3 |

1’ 29’36 |

+7.3 |

||

ME 4 |

4 |

12 |

23 |

0.8 |

1’ 25’56 |

+2.9 |

||

ME 6 |

6 |

16 |

32 |

1’ 25’56 |

+3.2 |

|||

ME 80 |

80 |

115 |

120 |

196 |

40 |

2.5 |

1’ 25’56 |

+7.8 |

ME 100 |

100 |

144 |

150 |

232 |

65 |

2.5 |

1’ 25’56 |

+9.3 |

ME 120 |

120 |

172 |

180 |

268 |

80 |

2.5 |

1’ 25’56 |

+8.4 |

ME 160 |

160 |

230 |

240 |

340 |

100 |

3 |

1’ 25’56 |

+10.9 |

ME 200 |

200 |

280 |

290 |

412 |

100 |

3 |

1’ 25’56 |

+10.3 |

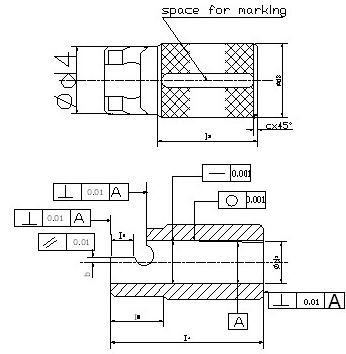

TABLE 1 DIMENSION OF TAPER PLUG GAUGES, PLAIN

Designation of Taper |

d js5 |

d2 H11 |

d3 |

Dia d4 |

I H11 |

I2 |

I H8 |

c |

B K6 |

a/2 |

AT µm |

MT 0 |

9.045 |

6.7 |

9 |

18 |

56.5 |

6.5 |

46.0 |

1 |

2.01 |

1’ 29’27 |

-3.7 |

MT 1 |

12.065 |

9.7 |

11 |

26 |

62 |

8.5 |

48.5 |

1 |

2.66 |

1’ 25’43 |

-3.9 |

MT 2 |

17.750 |

14.9 |

13.5 |

35 |

75 |

10.0 |

59 |

1.6 |

3.21 |

1’ 25’50 |

-4.7 |

MT 3 |

23.825 |

20.2 |

17.5 |

43 |

94 |

13 |

74 |

1.6 |

4.01 |

1’ 26’16 |

-4.7 |

MT 4 |

31.267 |

26.5 |

25 |

52 |

117.5 |

16 |

93.5 |

2 |

6.01 |

1’ 29’15 |

-5.9 |

MT 5 |

44.399 |

38.2 |

34 |

68 |

149.5 |

19 |

120.5 |

2 |

8.01 |

1’ 30’26 |

-6.0 |

MT 6 |

63.348 |

54.8 |

34 |

90 |

210 |

27 |

170 |

2.5 |

9.56 |

1’ 29’36 |

-6.8 |

ME 80 |

80 |

71.5 |

34 |

115 |

220 |

24 |

172 |

2.5 |

13.03 |

1’ 25’56 |

-6.9 |

ME 100 |

100 |

90 |

34 |

144 |

260 |

28 |

202 |

2.5 |

16.06 |

1’ 25’56 |

-8.1 |

ME 120 |

120 |

108.5 |

40 |

172 |

300 |

32 |

232 |

2.5 |

19.06 |

1’ 25’56 |

-9.3 |

ME 160 |

160 |

145.5 |

40 |

240 |

380 |

40 |

292 |

3.0 |

25.06 |

1’ 25’56 |

-9.3 |

ME 200 |

200 |

182.5 |

40 |

380 |

460 |

48 |

352 |

3.0 |

31.06 |

1’ 25’56 |

-11.3 |